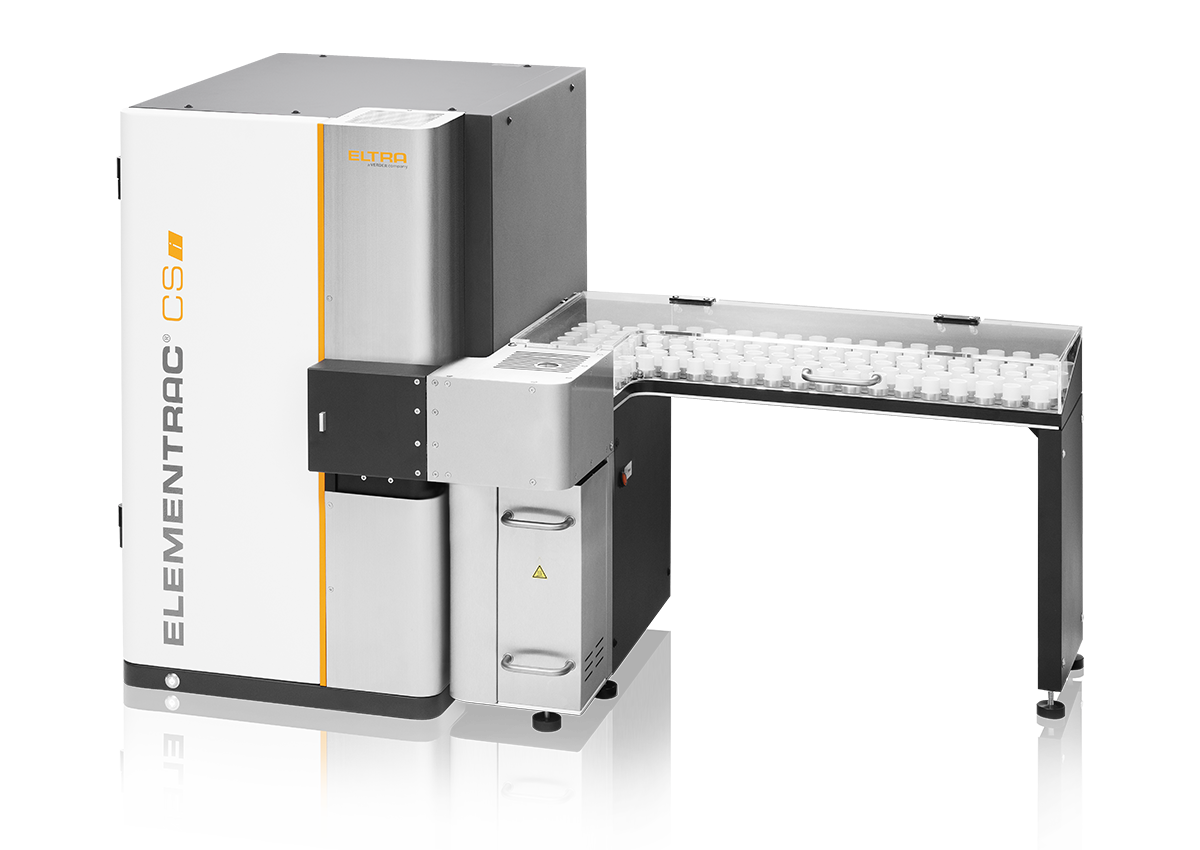

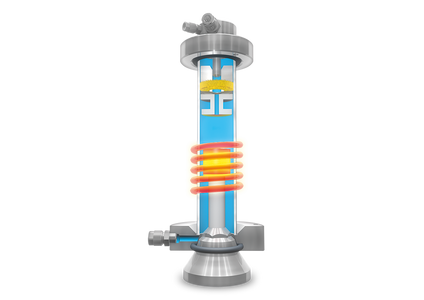

The elemental analyzer ELEMENTRAC CS-i measures the carbon and sulfur concentration in predominantly inorganic samples through combustion in an induction furnace and the subsequent analysis of the gaseous combustion products carbon dioxide and sulfur dioxide.

The high temperature of more than 2000 °C ensures complete decomposition of the sample and thus reliable and accurate elemental analysis over a wide concentration range.

The ELEMENTRAC CS-i meets and exceeds the requirements of all common standards for carbon and sulfur measurement, such as ASTM E1019, DIN EN ISO 15350.

Анализатор углерода / серы ELEMENTRAC CS-I

- Control of induction performance provides precise analysis of low-melting metals

- Heated dust trap allows for improved sulfur detection

- Platinum-based catalyst reactor ensures accurate carbon detection

- Carrier gas flow optimized for dusty samples

- Software-based leakage test

- Optional vacuum system, also available with dust filter class H for potentially harmful samples

- Single and multipoint calibration

- Robust design allows usage in production control and laboratory

- Low maintenance

Анализатор углерода / серы ELEMENTRAC CS-I Operation and Analysis Process

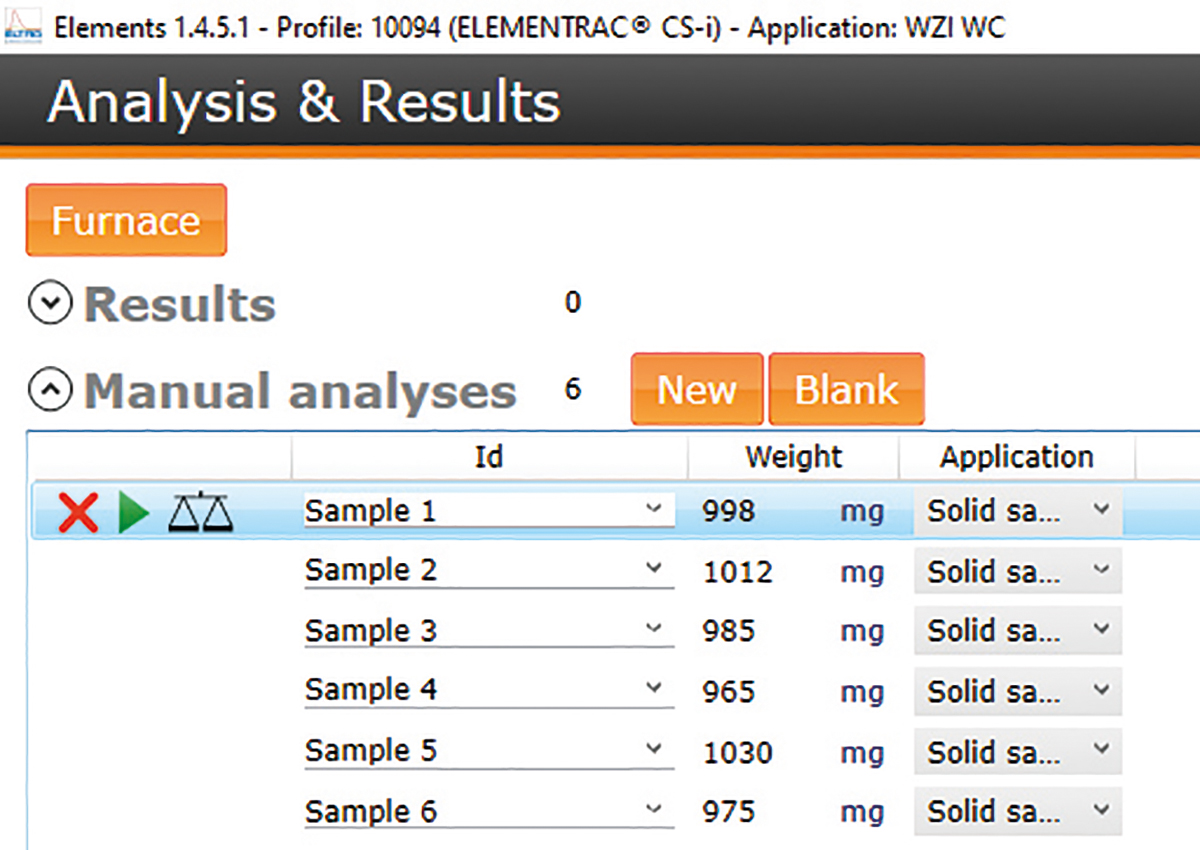

Step 1: Logging the sample into the ELEMENTS software

Step 2: Weighing and adding of accelerators

Sample volumes of 50 mg to 1000 mg are typical for C/S analysis. The sample is weighed in a ceramic crucible and accelerators like tungsten are added. The geometry of the sample (e. g. wire, powder, pin etc.) is not essential for a reliable analysis.

Step 3: Analysis

The ceramic crucible is then placed on the pedestal and the analysis is started via the ELEMENTS software. The software controls all subsequent steps like combustion and evaluation.

Step 4: Data output and export

45-60 seconds after the analysis has started, the measured carbon and sulfur concentrations are available for export as a report or via LIMS.

Анализатор углерода / серы ELEMENTRAC CS-I Configurations

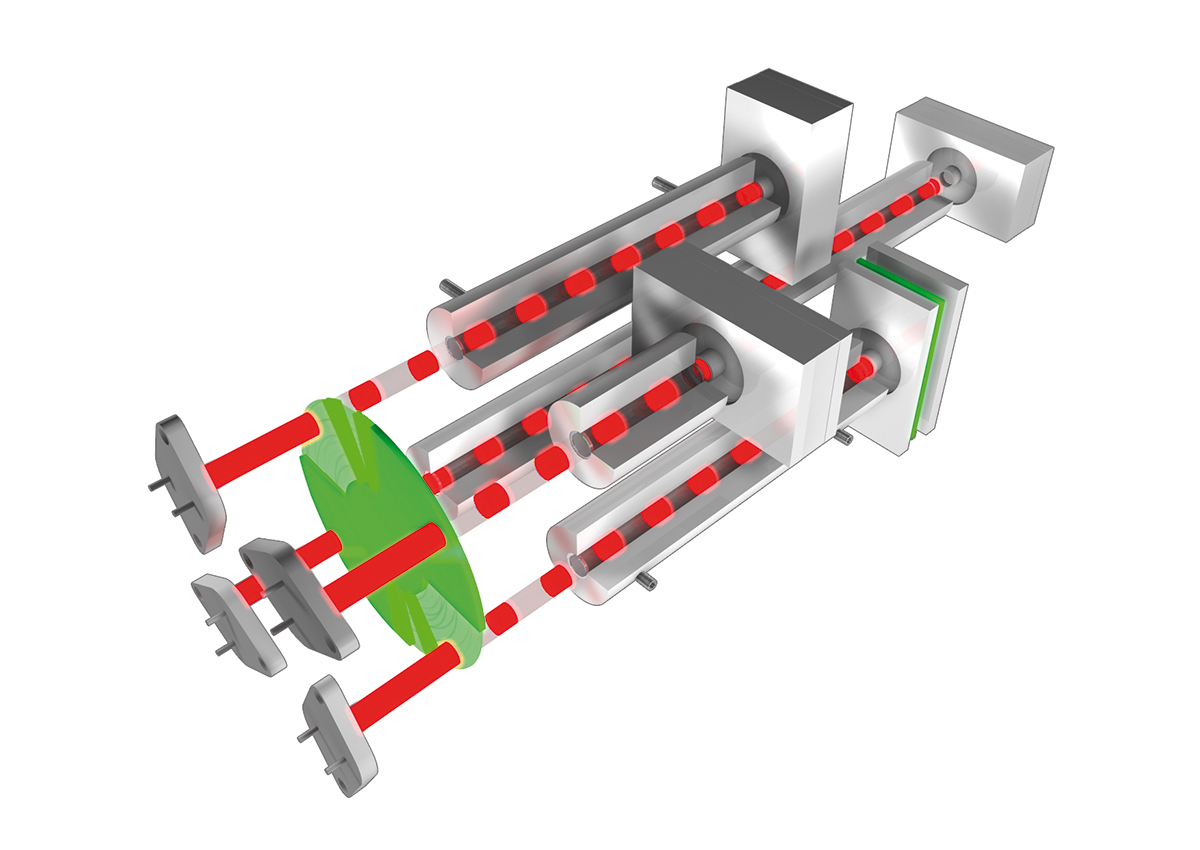

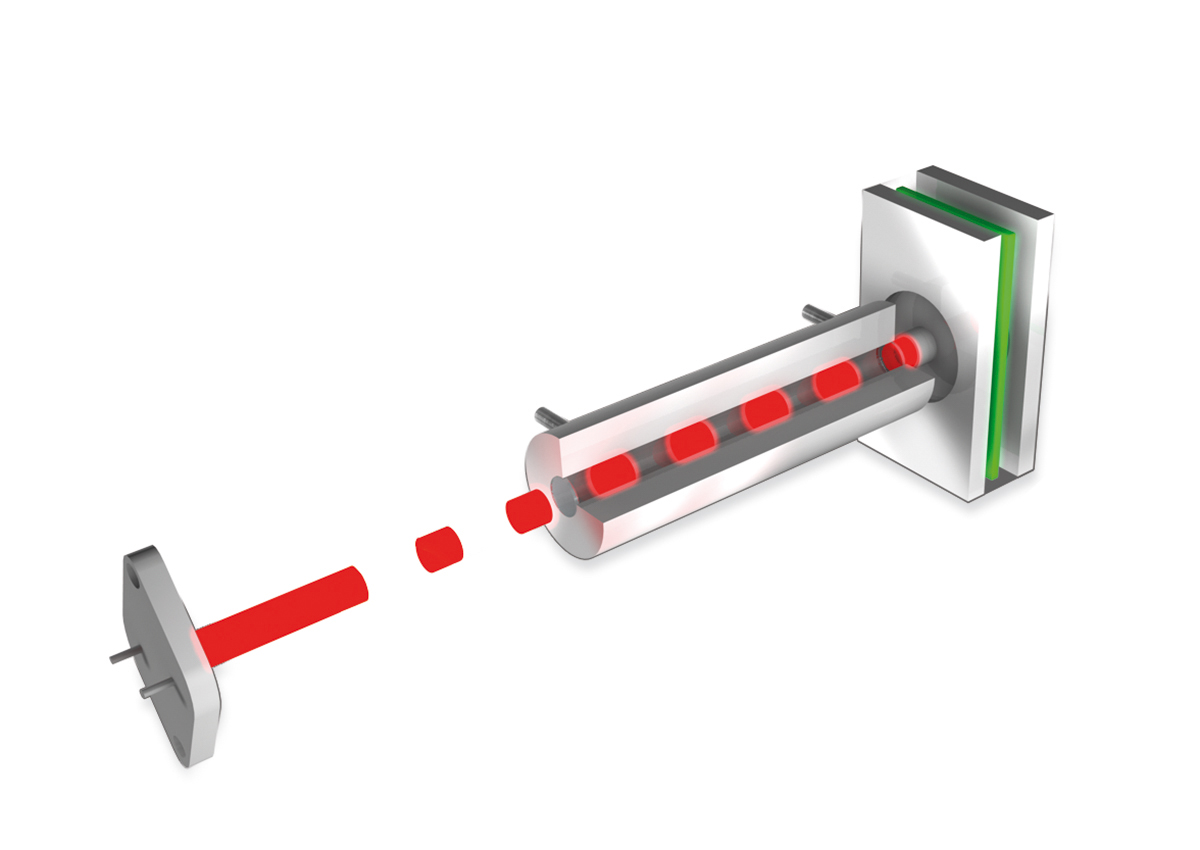

The ELEMENTRAC CS-i is available as a single-element analyzer for carbon or sulfur only, or in a configuration for simultaneous measurement of both carbon and sulfur. It uses up to 4 IR cells which can be configured according to customer requirements. The longer the cuvette, the more sensitive it is for low concentrations like 10 ppm. Shorter cuvettes also allow measurement in the low ppm range, however with increasing standard deviation of the measured values. For optimum analysis of low and high concentrations, a configuration of two IR cells for one element should be selected. The latest detector technology permits advanced configurations to reliably cover the measuring range from 0.6 ppm to more than 6 % for a sample weight of 1000 mg. Optional gold cuvettes provide higher reliability for elemental analysis of halogenated samples. For reliable analysis of materials with a high sulfur content, the CS-i can be equipped with more robust IR cells to extend the measurement range and improve the reproducibility of the results. It is also possible to equip the CS-i with a halogen trap. Another option is a special configuration for measuring cement.

Infrared cells with flexible measuring range

Cuvette with variable length

Анализатор углерода / серы ELEMENTRAC CS-I Integrated Standard Solutions

Catalyst

- For accurate carbon determination

- Extended reaction path ensures complete oxidation of incomplete combustion products (carbon monoxide)

- Best possible reproducibility even for very high carbon concentrations

Heated Dust Trap

- The dust generated by inductive combustion is collected in an external dust filter

- Efficient heating of the dust trap prevents condensation of water vapor

- Significant improvement of recovery rates and reproducibility of sulfur measurements

Intelligent Lance Management / Oxygen Supply

- Individual control of the oxygen supply during inductive combustion

- A lance flushes the entire oxygen flow to the center of the crucible to ensure complete oxidation of the carbon and sulfur contained in the sample (solid samples)

- Oxygen flow is supplied through the combustion chamber to avoid swirling and loss of sample material (dusty samples)

- Accurate analysis of low-density samples

Control of Induction Power

- For optimized combustion of metals with a low melting point, such as copper, tin or magnesium

- Reduced power in the induction furnace allows for safe and accurate analysis without sample loss through splashing during heating

Анализатор углерода / серы ELEMENTRAC CS-i Options

In addition to the features already integrated in the ELEMENTRAC CS-i further options are available to increase efficiency and extend the application range.

Autoloader

The induction furnace of the ELEMENTRAC CS-i can be equipped with an optional automatic sample loader. The standard module offers 36 crucible positions, the XL model even features 130 positions. It is the largest Autoloader available in the market for this type of application.

TIC Module

Carbon can be determined as total carbon (TC) or in fractions, i. e. total organic carbon (TOC) or total inorganic carbon (TIC). When combined with the CS-i, ELTRA’s TIC module measures the TIC content (e. g. lime) by acidification in products like soil or construction materials.

ELEMENTRAC CS‑i Glovebox

With the new ELEMENTRAC CS‑i Glovebox variant, we are expanding our portfolio with powerful solutions for controlled‑atmosphere analysis. The model is engineered for seamless glovebox integration, ensuring precise, reliable results while protecting both sensitive samples and users.

IoT - Internet of things The platform for remote access to your devices

- Real-time Monitoring: Gain insight into the status of your machines at any time thanks to immediate access to important data.

- Live Notifications: Stay up to date on the status of your devices with instant notifications.

- Effortless Backup: Whether you need to back up a single device or an entire fleet, back up your data effortlessly and minimize downtime.

- Automatic Software Updates: Verder Scientific IoT keeps your device software up to date, optimizing performance and reliability.

- Access to Analyses Data: ELTRA analyzers offer remote access to analysis data. This allows you to conveniently access important data while on the move.

- Autoloader Efficiency: Get the most out of remote analysis preparation with our autoloader feature, which ensures uninterrupted operation and increased productivity for all instruments equipped with it.

Experience the power of the Verder Scientific IoT platform today and unlock the full potential of your ELTRA analyzers!

Анализатор углерода / серы ELEMENTRAC CS-i Программное обеспечение ELEMENTS

The comprehensive Windows-based ELEMENTS software is an essential part of all ELEMENTRAC generation elemental analyzers.

A central window (analysis and results) is the starting point from which all functionalities required for the daily routine are easily accessible. From here it is possible to group and export analyzed samples, or register and analyze new ones. The user may call up various subordinate functionalities like application settings, calibration, diagnosis, or status.

Анализатор углерода / серы ELEMENTRAC CS-i Типичные Образцы Материалов

сплавы, алюминий, зола, карбиды, чугун, цемент, керамика, медь, ферросплавы, стекло, гипс, железо, известняк, металлы, минералы, руды, огнеупоры, песок, кремний, шлак, почва, сталь, ...

Анализатор углерода / серы ELEMENTRAC CS-i Принцип работы

In the induction furnace of the elemental analyzer the sample is melted in a pure oxygen atmosphere, causing sulfur to react to sulfur dioxide (SO2) and carbon to a mixture of carbon monoxide (CO) and carbon dioxide (CO2). The combustion gases pass through a dust filter and moisture absorber for purification. In the next step the sulfur dioxide is detected in infrared cells. In the CS-i infrared cells with different sensitivities (high/low) can be adapted according to the user’s requirements. Oxidation of both, carbon monoxide to carbon dioxide and sulfur dioxide to sulfur trioxide follow the sulfur measurement. The SO3 gas is removed with cellulose wool; the carbon content is detected by infrared cells which can be individually customized. The ELEMENTRAC CS-i elemental analyzer can be equipped with up to 4 independent infrared cells.

Анализатор углерода / серы ELEMENTRAC CS-i Характеристики

| Measured elements | carbon, sulfur |

|---|---|

| Samples | inorganic |

| Furnace alignment | vertical |

| Field of application | construction materials, engineering / electronics, geology / mining, glass / ceramics, steel / metallurgy |

| Furnace | induction furnace, above 2,000 °C |

| Detection method | solid state infrared absorption |

| Number of IR cells | 1 - 4 |

| Material of IR path | aluminum (optional gold) |

| Typical analysis time | 40 seconds (nominal) |

| Chemicals required | magnesium perchlorate, sodium hydroxide, platinum-based catalyst |

| Gas required | compressed air (4 bar/ 60 psi)//oxygen 99.5 % pure (2 - 4 bar / 30 - 60 psi) |

| Power requirements | 230 V, 50/60 Hz, max. 15 A, 3450 W |

| Dimensions (W x H x D) | 52 x 84 x 75 cm |

| Weight | ~ 150 kg |

| Required equipment | PC, monitor, balance (resolution 0.0001g) |

| Optional accessories | Autoloader (for 36 crucibles), HTF-540 pre-heating furnace, halogen trap, carrier gas purification, vacuum cleaner |